LaGuardia Airport is one of the busiest airports in the United States. In 2015, a significant investment was ear-marked to upgrade airport infrastructure with improved transportation access, eight miles of roadway including 24 new bridges, additional airside taxiways, and world-class passenger amenities.

In 2018, ParkUSA was contacted to engineer hatchway lid assemblies for sanitary sewer pump lift stations located in the basement of LaGuardia Airport, Concourse B. These lids were designed to retain up to ten feet of hydrostatic pressure head (4.33 psig) and prevent flooding caused by excessive stormwater drainage that back flowed into the lift stations.

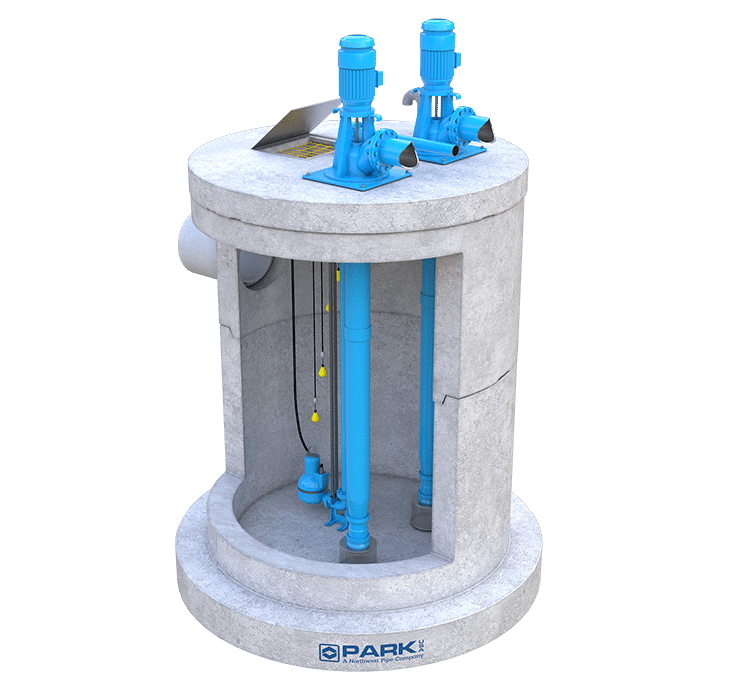

Later in 2019, ParkUSA was again contacted to complete a similar project in Concourse A. However, for this project the hatchway lid assemblies were required to retain up to 15 feet of hydrostatic pressure head (6.5 psig). ParkUSA relied upon its in-house engineering and fabrication capabilities to manufacture four hatchway lid assemblies. These assemblies functioned with a 72” x 72” ID lift station, consisting of a square structure that accommodated the following:

- One 30” x 40” hatchway

- Four 4” pipe connections for pump discharges and venting

- One 2” threaded electrical connections.

Each assembly was hot dipped galvanized for increased performance and durability and designed to be watertight up to fifteen feet of hydrostatic pressure head, or 6.50 psig. Upon completion of the fabrication process, the hatchway assemblies were factory performance tested to ensure all project requirements were achieved.