Issue

There is no one set of national standards which establishes requirements for emergency water supplies of health care facilities. However, on June 12, 2002, President Bush signed into law the Public Health Security and Bioterrorism Preparedness and Response Act of 2002. The act requires community water systems, serving populations greater than 3,300, to either prepare or revise an emergency response plan. In developing the plan, community water systems are encouraged to include hospitals.

The Joint Commission on the Accreditation of Healthcare Organizations (JCAHO), an independent non-profit national accreditation organization, has established the standard EM.02.02.09 requiring hospital emergency operation plans to identify procedures if the hospital cannot be supported by a local community for at least 96 hours relative to water, wastewater disposal, power and heating fuels. Although JCAHO is not a governmental agency, for health care facilities to maintain their accreditation, they must comply with the standard.

The Center for Medicare and Medicaid Services Conditions for Participation/Conditions for Coverage (42 CFR 482.41) requires that health care facilities must include emergency gas and water supply. This requirement has bearing on those health care facilities that treat Medicare and Medicaid recipients.

States and local municipalities may include requirements within their building and/or plumbing codes.

For example: California has addressed the issue through their building and plumbing codes. SB 1953 (1994), an amendment to the Alfred E. Alquist Hospital Facilities Seismic Safety Act (SB 519 HSSA) of 1973, established five nonstructural performance categories for acute care hospital facilities. These categories include expiration dates with the goal to have all acute care hospital facilities meeting NPC-5, the most stringent category, by 2030. NPC- 5 requires an on-site water supply, holding tanks for wastewater, and fuel supply for 72 hours of emergency operations. Compliance is mandated by 2030, or the facility will be removed from acute care service.

California Plumbing Code Section 614.4.1 states: “For acute care hospital facilities required to meet NPC-5, an on-site water supply of 150 gallons (based on 50 gallons/day/bed for 72 hours) of potable water per licensed bed shall be provided. The emergency supply shall have fittings to allow for replenishment of the water supply from transportable sources.”

Emergency Potable Water System

To maintain accreditation with Joint Commission on the Accreditation of Healthcare Organizations (JCAHO), an Acute Care Facility needs an emergency potable water supply sufficient to service the facility for 96 hours. Per California Plumbing Code Section 614.4.1 an Acute Care Facility must supply an on-site water supply of 150 gallons (based on 50 gallons/day/bed for 72 hours) of potable water per licensed bed.

ParkUSA® offers an emergency potable water system that is integrated into the facility’s potable water system. When there is a disruption in the water service, diverter valves are activated, enabling the backup water supply. The emergency potable water system becomes the facility’s source of potable water for the designed capacity (72 hours or 96 hours). The system comes with an external connector to allow for replenishment of the water supply from transportable sources if the emergency continues past the design period. Potable water storage tanks are utilized to store water onsite in aboveground or belowground configurations. Tank material can consist of: corrugated steel, fiberglass, high density polyethylene and precast concrete.

Wastewater Holding Tank

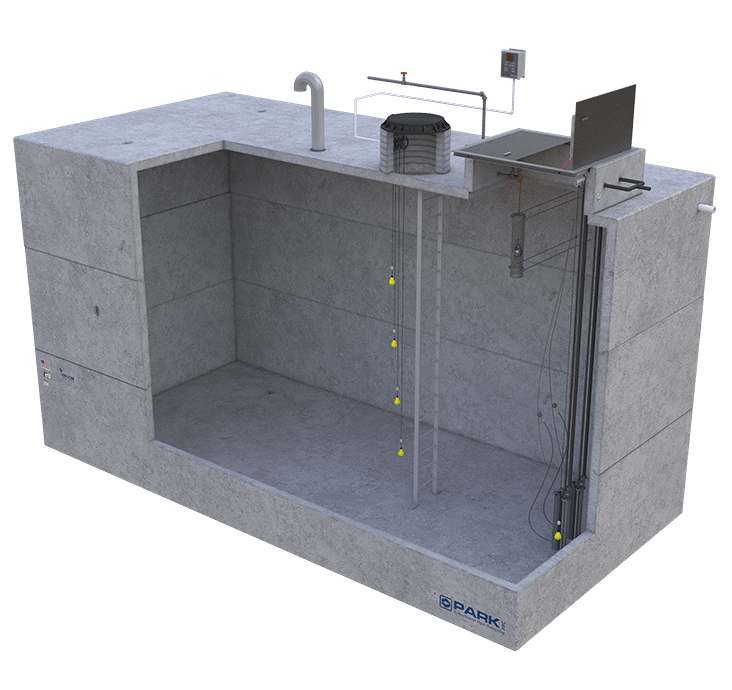

The ParkUSA® DeConTank® Series is a holding tank system for the safe containment of sanitary waste or contaminated wastewater. The system is engineered to hold sanitary wastewater when a facility’s wastewater treatment system is not operational or inaccessible. The DeConTank® system also includes an option to intercept and store hazardous wastewater discharged from decontamination rinse showers and isolation activities.

The DeConTank® system features direct bury and aboveground models, sized from 50 to 10,000 gallons. The storage tank is double walled and available in three different materials, precast concrete, fiberglass or stainless steel. The control system includes high level leak detection and a diverter valve system. The diverter valve system is a new innovation that allows for greater utilization for hospital facilities. The hospital personnel can control the shower discharge to either sanitary sewer or the DeConTank® for decontamination activities.

The DeConTank® system can be designed with a pump system to empty the storage tank contents into the sanitary sewer system once the system is operational. If the optional dual system (Decontamination and Emergency Storage) is chosen, the tank includes a pump port with camlock fitting for remote pump out and a vent with an activated carbon filter.

Fuel Tank with Spill Containment

The SuperVault® MH is the first tank to pass the SwRI 95-03 Multi-Hazard test, the toughest national test for aboveground fuel tanks. The SuperVault® MH has been tested for multiple exposure to fires and other hazards, plus an extended element exposure test. This means that if the SuperVault® MH experiences a hazard, it may be recertified and kept in service rather than having to be replaced.In addition to SwRI 95-03, the listing includes a 4-hour fire rating. It meets the stringent safety requirements of Uniform Fire Code Appendix Standard A-II-F-1 (UFC 79-7), SwRI Test Procedure 93-01, NFPA 30/30A, and UL 2085 Protected Tank 20-Year transferable warranty. Seismic restraints are part of every tank.External diking not required by UFC.

SuperVault® MH is offered in two configurations, cylindrical and rectangular. The cylindrical line is available from 250 gallons to 20,000 gallons. The rectangular line is available from 250 gallons to 2,000 gallons. Components that are part of the system include: spill containment basin, shut-off device, overfill alarm, leak sensors, emergency vent. An optional generator for the fuel tank system is available.

Our Responsibility

ParkUSA® believes in water technology development to combine efficiency and environmentally friendly products. ParkUSA’s goal is to offer its customers sustainable green solutions that meet today’s needs, as well as anticipated changes in regulations.

Contact us for more information and design assistance.