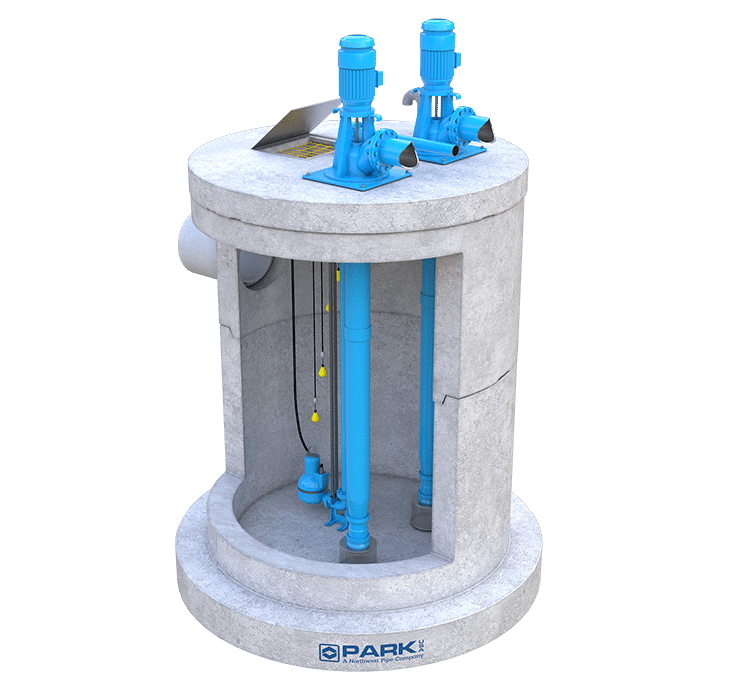

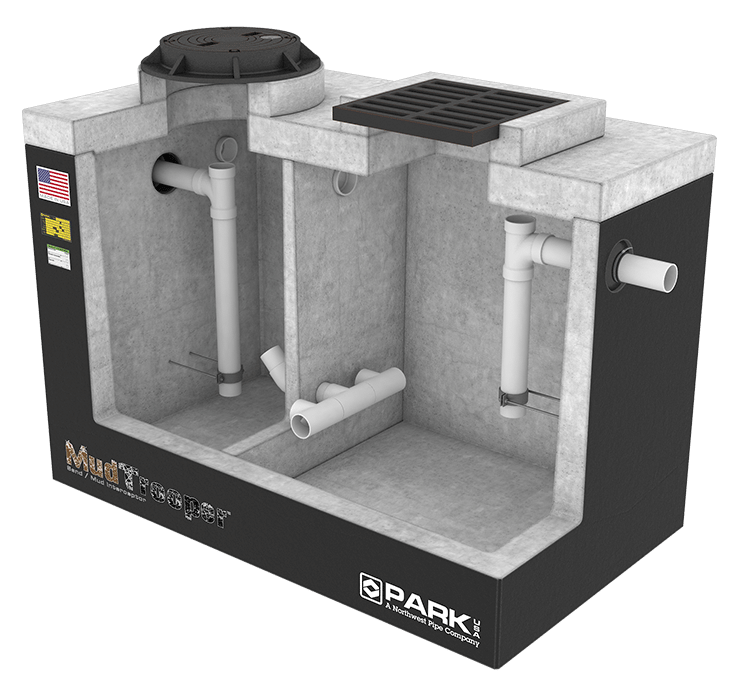

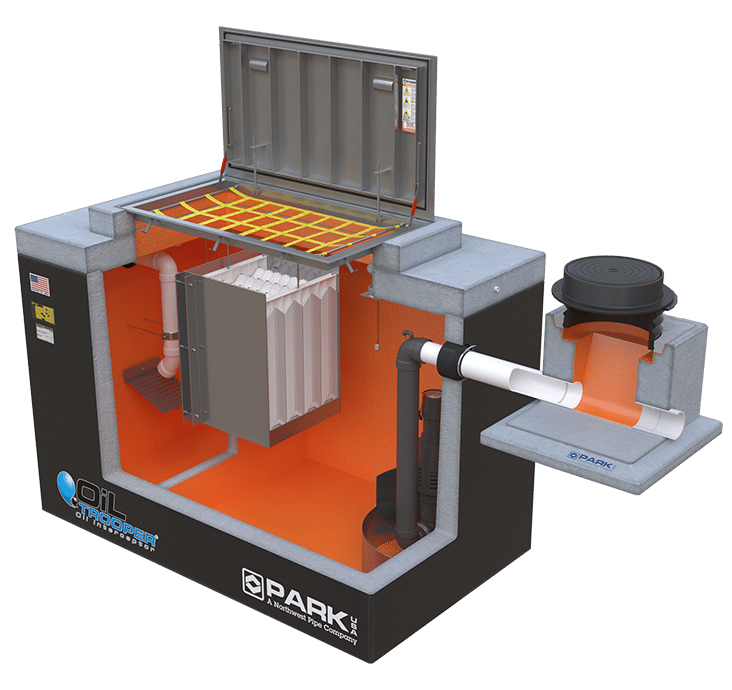

The Caldwell Cayon project includes five ParkUSA products delivered to a mining facility in Soda Springs, Idaho. The products include a 5,000-gallon Sand-Mud Interceptor, a 2,500-gallon Oil-Water Separator, a 1,000-gallon Oil-Water Separator, and two Pump Lift Stations, each encased in a precast concrete structure.

All the precast vaults were manufactured at our Geneva Pipe and Precast plants in Utah. The internal operating components were built at our ParkUSA facility in Houston, Texas, and shipped to Utah where they were assembled in each unit. Manufacturing the large precast components in Utah rather than Texas allows our product to travel to Idaho at a much lower cost.

The equipment arrived in Idaho ready for connection, with all mechanical components installed inside each precast structure. The pre-assembled units are shop tested in Utah and can be dropped in place on-site with minimal specialty contractor effort and at the discretion of the project schedule.

The Sand-Mud Interceptor, the 2,500-gallon Oil-Water Separator, and the two Pump Lift Stations form the treatment train for the wash bay reclaim system. The wash bay area services all heavy equipment and vehicle cleaning for the phosphate mining and phosphorus manufacturing facility. After cleaning, polluted water leaves the wash pad and circulates through the sand-mud interceptor to remove sand and grit from the water. The water then travels through the Oil-Water Separator to remove oil from the water. The two Pump Lift Stations recirculate the water.

The 1,000-gallon Oil-Water Separator is used in another area of the manufacturing facility. Both Oil-Water Separators include an automatic notification system that utilizes a tank-mounted oil-water interface sensor to monitor the oil level. When the oil level is near maximum capacity, the system emits a visual and audio alert to notify the maintenance team.